Reinke Systems Are All About the Details!

Other manufacturers don’t put as much stock in the details as we do. Features such as long sweep bottom elbows, internal flex joints and high-strength steel give Reinke Systems endurance and performance power.

We are internationally known as a premier manufacturer and provider of the finest steel, stainless steel and aluminum irrigation systems and components. We offer more choices. Superior quality. Comprehensive service after the sale. That’s our tradition and that’s why we’re an industry leader.

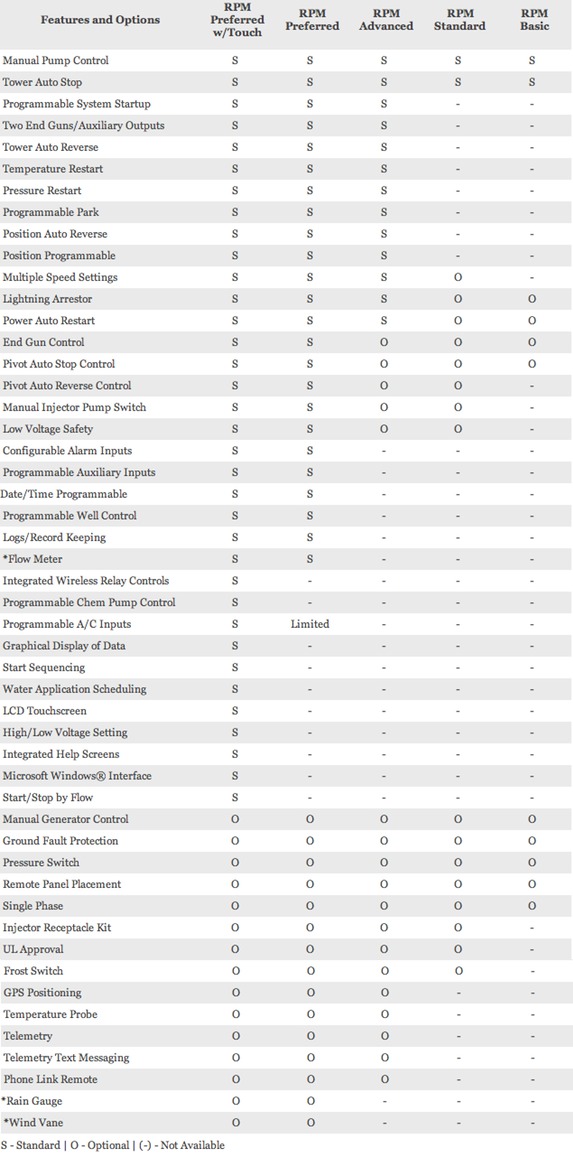

Control Panels

Our line of Reinke Precision Management (RPM) control panels lets you choose your level of control from manual in-field settings to programming pivot operation.

Match Tires to Your System

Don’t neglect to coordinate tire size to your new Reinke system. Match span weight and tire size to soil and terrain conditions to maximize application while minimizing rutting.

- 11 x 22.5

- 11.2 x 24

- 14.9 x 24 (for turf)

- 14.9 x 24

- 16.9 x 24

- 11.2 x 38

- 13.6 x 38

Representative tire sizes shown.

Agri-TRAC

Agri-TRAC

Benefits:

- Increase Flotation

- The Agri-TRAC provides 5 times as much ground surface area. Its concave shape and unique rolling action reduces wheel rut depths by 80%. The Agri-TRAC prevents center pivots and lateral move systems from getting stuck in the mud even on the most difficult soils.

- Increase Traction

- The tire tread bars mesh with the Agri-TRAC treads and will not slip inside the track even on hills with slippery soils. The Agri-TRAC provides 10 times as much tread length and traction.

- Operates Smoothly

- The Agri-TRAC rolls smoothly on small diameter tires (11 x 22.5 recaps) without increasing the load on gearboxes. Expensive high flotation tires or large diameter tires are no longer needed. The Agri-TRAC protects tires from sharp rocks and rotting sunlight.

- Quality Construction

- The Agri-TRAC is warranted for one year against defects in materials or workmanship. The Agri-TRAC is hot dip galvanized to prevent rust and corrosion.

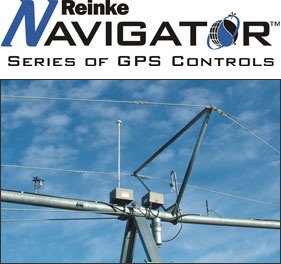

Navigator Series of GPS Controls

The more accurate your irrigation system, the greater the results. To get everything you can out of your system, incorporate the Reinke Navigator Series of GPS Controls for end towers, lateral move systems and swing arm corners. The Navigator is designed for those situations that require extreme accuracy in timing and application in difficult-to-cover acreage.

The more accurate your irrigation system, the greater the results. To get everything you can out of your system, incorporate the Reinke Navigator Series of GPS Controls for end towers, lateral move systems and swing arm corners. The Navigator is designed for those situations that require extreme accuracy in timing and application in difficult-to-cover acreage.

This advanced satellite-guidance technology can eliminate many problems producers face, including inaccurate end gun timing and the hazards of buried wire guidance. With features including WAAS-enabled technology and surveyor-grade equipment, the Navigator line provides reliable, accurate guidance and position information for your system.

End Tower Location

- Better end gun control with all system configurations.

- WAAS-enabled for unprecedented accuracy.

- Can be added to any system with a Reinke R.A.M.S. panel or PAC II timer.

- Add extra options without the expense of additional span cable.

Lateral Move System And Swing Arm Corner Guidance

- Eliminates the need for buried wire, cable or furrow guidance.

- Can be used on all Reinke lateral move systems.

- One stationary receiver can operate multiple systems.

- Surveyor-grade equipment.

Drivetrain

Center Drive – High efficiency gear motor delivers exceptional torque to propel your system over the roughest terrain and through difficult soil conditions.

Center Drive – High efficiency gear motor delivers exceptional torque to propel your system over the roughest terrain and through difficult soil conditions.

3 Output RPMs

- Low 60:1 ratio or 29 RPM

- Standard 40:1 ratio or 43 RPM

- High 25:1 ratio or 70 RPM

Helical Gear Design – 95% efficiency

- All aluminum gear case and motor housing assures cooler running, longer life and increased corrosion resistance

- Multi-bolt mounting pattern fits most brands

- High-strength steel shafting provides long life and dependability

- Thermally protected with automatic reset located in easily accessible junction box

- Heat-treated gears

- Specially designed input and output seals

- Top fill plug positioned to set correct oil level

- All critical electrical connections are encapsulated to resist moisture penetration

- Use of smaller generators and smaller incoming wire sizes is possible

- C.S.A. approved

- Stainless junction box cover

- Dual shaft seals

- New high capacity outer motor bearing

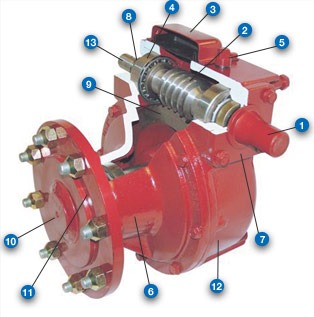

Heavy-Duty Wheel Gearbox Redefines Durability

Backed by the industry’s best warranty, covering the cost for both the gearbox and labor, Reinke gearboxes are built to provide years of dependable service.

- Input shaft cover snaps on to either end to guard against seal and shaft damage

- Unique rolling diaphragm design minimizes positive and negative pressure build-up during operation – relieving negative pressure prevents water and contaminants from being drawn into the gear case

- Stainless steel diaphragm cover provides years of corrosion-free life

- Larger input bearings (largest in the industry) provide 55% greater load capacity for today’s larger tires and faster rotation times

- Non-seizing drain and fill plug for easy maintenance

- Cartridge style input and output seals utilize a multi-lip design and a precision ground, polished sealing surface to all but eliminate oil leaks

- End cap is machined from cast steel to handle the higher loads created with today’s larger tires

- Seal protector blocks out contaminants and extends seal life

- New Bull Gear, designed for greater tooth contact, results in higher load capacity and longer life

- Large 2 1/4" diameter output shaft and flange are made of high-strength steel to carry tower loads

- Centering ring doubles as a load-bearing surface, relieving stress on the lug bolts and lessening potential wheel damage

- Reinforced housing provides more material in high stress areas, increasing overall gearbox strength

- Dual input shaft provides universal mounting

- Output seal features two double-lipped seals with grease-filled gap for extended life

Replacing the standard gear oil with Sprinkler Lube 1200™ after the first season will provide exceptional lubrication with minimal maintenance while extending the life of the wheel gears.

High Strength Materials

The Reinke Electrogator II, Alumigator IV, and Minigator E2045 are designed to be strong and NOT HEAVY. This is accomplished through the innovative use of high-strength materials and engineering design. Standard steel is strong compared to many other materials such as copper, brass, wood, etc. However, with the addition of alloying elements, steel can be strengthened by 40% or more. Reinke uses what is referred to as “high-strength, low alloy steel”. This type of steel gives us the ability to weld and work it like standard steel. The automotive industry developed and uses this type of steel in order to make their vehicles stronger yet lighter and more efficient.

How does this benefit you? A typical 8 tower, 1300’ Reinke system can weigh as much as 3 tons less than a competitive system of similar spans and length. Less weight equates to less wheel tracks, less stress and wear on the drive train and system components, less downtime and maintenance expense, more dependable, more reliable, and more cost efficient over the life of the system. Reinke is the only irrigation company that is bringing you the latest in steel technology and has done so for more than 35 years. This Reinke exclusive makes for a better irrigation system and a better irrigation value.

V-Ring Seal

Reinke’s exclusive V-Ring seal provides a much stronger flange-to-flange connection that will not allow spans to sag or settle over time. Enclosed inside metal flange to metal flange pipe connections, the V-Ring seal creates no flow restriction in the pipe and is never exposed to the sun, eliminating potential UV damage. Reinke’s V-Ring seal can save you thousands of dollars over the life of the system by never having to change them. The V-Ring seal carries a 25-Year Warranty, the longest in the industry.

Unique Internal Flex Joint

Reinke’s patented and exclusive, sometimes copied, Internal Flex joint encompasses only a 4 foot section of the water carrying pipe apart from the span pipe. This unique and versatile design allows Reinke water pipe to be interchangeable since the tower is attached to the joint and not the span pipe. The internal flex joint is a critical part of the flexibility and strength of a Reinke system. Three-axis flexibility with center-line rotation reduces structural stress and extends the boot life. Reinke’s innovative parallel linkage and alignment controls centered over the hinge point of every span, provides for a more precise alignment over varying terrain.

Indestructable Double Walled Tower Control Box

Reinke’s exclusive tower boxes provide a moisture-free environment for all electrical components. The doublewall box design eliminates condensation and keeps electrical components cool and dry. Reinke’s injection molded design results in the strongest, impact and corrosion resistant box in the industry. The mechanical safety interlock, exclusive to Reinke, prevents removal of the cover during operation. Reliability + safety = peace of mind.

Single Leg Tower Design

Durable and flexible, Reinke’s exclusive single-leg tower is the best in the industry. Engineered from high-strength steel to absorb stress that would normally be transferred to the pipeline, our tower design maximizes system life and reduces component fatigue – which translates to less wear and tear on the system, and less maintenance and ownership costs for you.